In this article down the page you can get a good deal of helpful material in regards to Simple Steps for Installing a Shower Base.

Updating a restroom is among the a lot more popular residence renovation projects. Managing the plumbing for draining your shower can be exceptionally simple unless you overdo it.

Handling Your Own Shower Drain Installment Project

Whether you are a bathtub or shower person, most individuals seek shower just choices when purchasing a residence. This easy reality implies greater than a few house owners invest a weekend upgrading or mounting showers in their bathrooms. Luckily for you, it is a rather simple process.

A collection agency or frying pan describes the straight surface area situated at the end of the shower. The collector generally includes a non-slip surface somewhat banked in the direction of the facility or anywhere the drain is located. Combined with three to 4 inch wall surfaces around the side, the objective of your shower drain plumbing is to get the water to flow to and also away.

You can literally build an enthusiast for your brand-new shower, yet you truly require to think of it. Do you actually wish to enter the complications of getting the sloping appropriate, in addition to ensuring every aspect of it is water-proof? As well as I mean every element! It is much easier to merely purchase a pre-cast enthusiast online or at your regional Lowes, Home Depot or equipment store. Structure one could sound like a great concept, however you will most likely really feel in a different way after a number of hrs.

Despite how you set about obtaining a pan, you should make every effort to utilize one that has the drainpipe situated in the same spot as the original pan. Moving the drain pipelines can be a task, especially if the building contractor utilized an one-of-a-kind framework framework. If you are identified to move the drain, you are going to need to cut back the pipeline or lengthen it, which may suggest destroying huge pieces of the flooring. Rephrase, you are going to be considering a several weekend job.

Assuming we have our drainpipe aligned, the actual link is relatively straightforward. The drain pipeline ought to be encountering vertical approximately the collector. It will typically look like a "U", which implies it serves as a cleanout to maintain nasty smells from returning up from the drain. To connect the drain, you are mosting likely to produce a water limited connection between a drainpipe cap on the top of the frying pan and the drain pipe. Solutions differ, but you are generally going to do this by putting a combining piece on the top of the water drainage pipeline. This is after that covered with gaskets and also literally screwed right into the drainpipe cap. The drainpipe cap should serve as a locknut, to wit, it screws directly onto the coupling.

The tricky part of this process is obtaining your drain cap to fit into a leak-proof setting in the pan. This is completed by withdrawing the drainpipe cap when you make certain every little thing meshes. Then, you placed plumbers putty around the bottom of the cap and afterwards screw it back on. The putty must create a tight seal in between the cap and the shower frying pan, which maintains water from trickling under it and right into the framing under the shower.

Undoubtedly, restroom showers come in a variety of styles nowadays. If you acquire a collector, they generally come with plumbing guidelines or the shop can keep in mind anything unusual you ought to understand. It seems intricate, yet is usually rather direct. Have fun!

STEEL BUILDERS

properly installed shower drain can be the difference between staying dry and disaster. The water flowing down your shower drain requires a proper outlet connection; otherwise, you run the risk of flooding.

With so many different types of drains on offer nowadays (from linear shower drains to grates of all shapes and sizes), there are lessons to be learned about each type before installing one yourself. Whether it’s standard or custom, Steel Builders is here to help you install your shower drain.

SMALL FLOOR WASTES

Small Floor Waste drain products are available in various patterns and sizes to suit a wide range of uses. Welded from 316 stainless steel, these small floor waste drains provide minimal visual impact and a sleek finish that will make your bathroom or shower stand out.

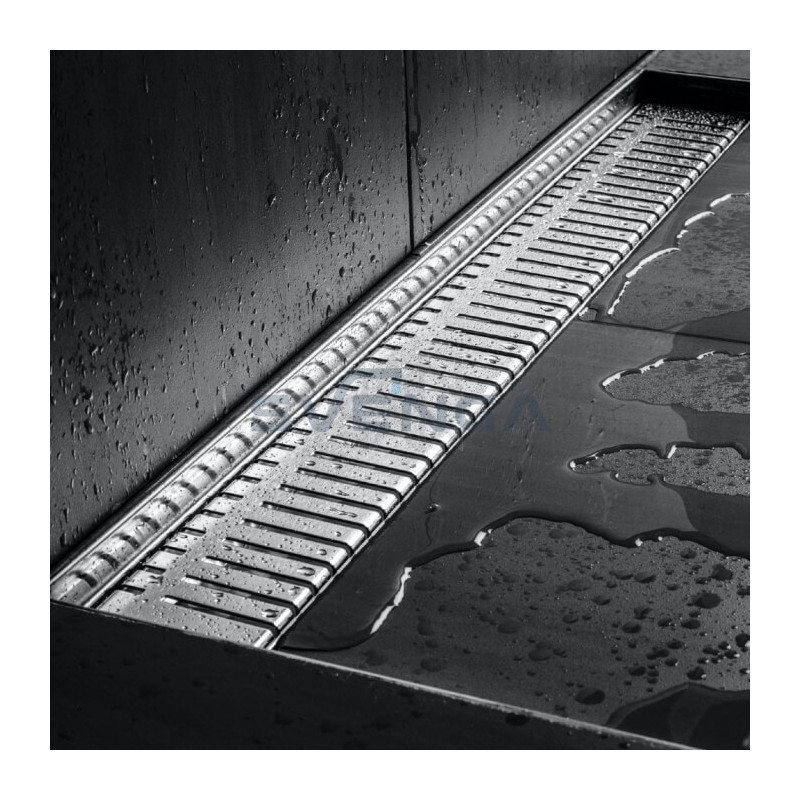

LINEAR SHOWER DRAIN

We’d love to tell you that you can just dig a hole, throw a grate on top and call it a day. But when it comes to installing a linear shower drain and grate, there’s a whole world of possibilities that go beyond functionality. Shower drains can actually add a great deal of value to your bathroom, with a variety of designs and finishes available. Get creative with your shower drains.

CUSTOM SHOWER GRATES

When a standard shower grate installation doesn’t work, you’ll need to consider a custom shower grate and drain modification to suit your application. We offer three top finishes: line patterns, heelguard or tiled inserts.

SHOWER GRATE INSTALLATION STEP BY STEP

- Start by removing everything to expose the drainage point. Depending on your bathroom and drain size, the drainage point will typically be 50mm, 80mm or 100mm in diameter.

- With everything out of the way, install the flange onto the floor, followed by your water stop angles.

- Waterproofing. Following Australian Standards, you’ll need to create a slope towards the floor flange. This ensures that any water that penetrates the grout will flow into the drainage point.

- With waterproofing complete, it’s time to install the grate. This is where you can start getting creative. Linear shower drain outlets can be installed in the centre, at either end of your shower or at a custom location.

- When a standard shower grate doesn’t work, Steel Builders can customise an existing shower grate to length or custom outlet position, which can be welded into place.

- Now we have to sand and cement the floor around the shower drain. Remember to leave enough space between the drain to glue your tiles slightly above the drain height.

- Fill the joint gap between the shower grate and the tiles with a flexible sealant adhesive to allow for expansion and contraction. Once the sealant has dried, it’s time to enjoy your brand new shower!

https://www.steelbuilders.com.au/blogs/news/how-to-install-a-shower-drain-steel-builders

:max_bytes(150000):strip_icc()/snake-a-clogged-shower-drain-2718775-hero-28269e681b8f46adb59c976f2d87944f.jpg)

As a person who reads about How to Install a Shower Drain in a Basement, I was thinking sharing that chunk was appropriate. Liked our posting? Please share it. Let others find it. Many thanks for your time. Kindly pay a visit to our site back soon.